Plastic custom profiles

Pre-made extruded profiles don’t always suit the needs of every company, and sometimes it is necessary for them to buy customized profiles so to ensure that their finished goods are of great quality, resistant and perfectly isolated. However, the businesses that manufacture this kind of objects are very few and those that have a long experience are even fewer, so it’s best to turn to experienced firms such as Plasticol.

Plasticol is an Italian company located in Samarate whose core business is the extrusion of plastic goods such as cables, pipes, and gaskets. In order to produce them it uses many kinds of plastic, like PVC, ABS or polyethylene. In its catalog, there are also polyurethane custom profiles, products created following the specific directions given by the clients, so to fit perfectly the other parts of a finished good.

Polyurethane custom profiles: the project

Whatever the material used for the manufacture of custom profiles is, there is one fundamental step that needs to be done before starting the creation of the profile itself: the design stage. This phase is essential to deliver high quality final goods to the clients.

Plasticol can count on an amazing team of professionals both in the engineering and the plastic extrusion departments who will help our customers to define the general project as well as the most suitable material to make it work. Once the material is chosen, our clients can decide to send us their own sketches or to use our team’s expertise in order to create the perfect design for the project.

During the design phase, we will also discuss details like color, packaging and stocking, digital prints on the products, and the possibility of plastic co-extrusion.

Polyurethane custom profiles: how we manufacture them

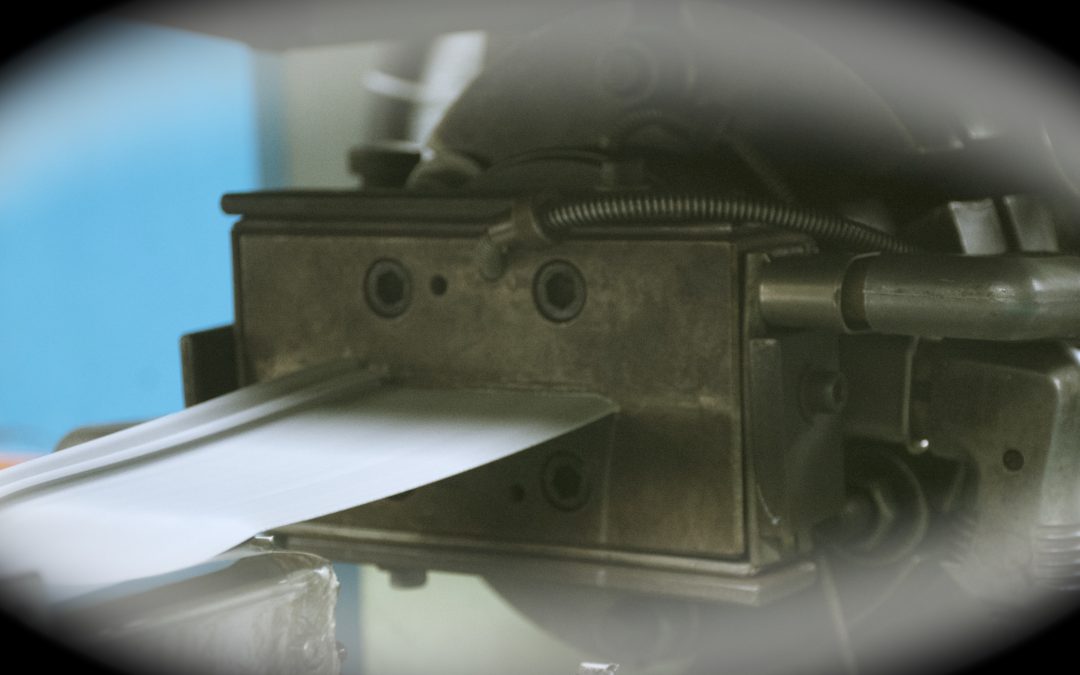

Polyurethane is a great material to work with because of its physicochemical characteristics. Once the client has settled for polyurethane as the material for its custom profiles, Plasticol can start building the mold. Thanks to super technological machinery we are able to create an object identical to the one in the original project.

After the mold is ready, Plasticol can start the extrusion process: the polyurethane granules are put into the extruder where the friction transforms them into a pliable dough which then comes out of the mold in the desired shape.

For more info about polyurethane, custom profiles get in touch with Plasticol.

Location:

Via San Carlo 35

21017- Samarate (VA)

Phone: (+39) 0331 234 212

Fax: (+39) 0331 235 108

Email: info@plasticol.it