Production of rigid plastic extrusions

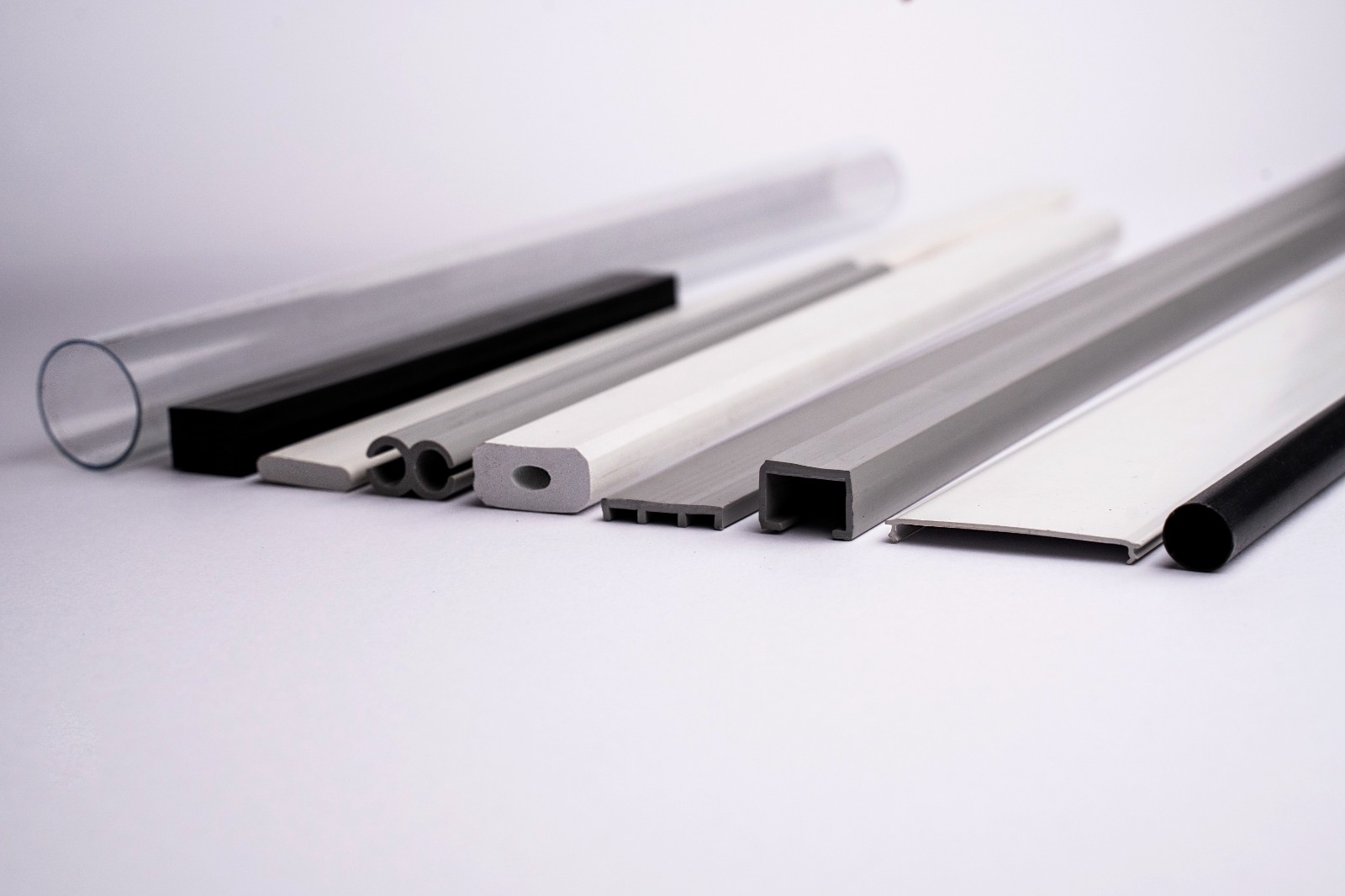

Among the types of plastic profiles produced by Plasticol there are also rigid profiles.

All made of a wide variety of plastic materials, rigid profiles are widely demanded by customers operating in different industries for their durability, strength and reliability. Our company is able to produce rigid profiles weighing less than 2 KG/MT.

Plasticol’s team is at customers disposal for any inquiry regarding product design, raw material and all the development process behind the profile.

The presence of an in-house staff of specialized technicians and workers allows us to create tailor-made moulds totally in line with customer requirements.

Our extruded rigid plastic profiles

Here are the rigid raw materials we manufacture:

Materials

The main rigid raw materials manufactured by Plasticol for the production of profiles, pipes, seals and gaskets are:

Rigid PVC

Polyvinyl chloride or PVC is one of the most widely used plastics in the world. The properties that make this material so functional in so many industrial fields are impermeability to liquids, gases and vapours, flexibility, good resistance to heat and chemicals, longevity, self-extinguishing, easiness of recycling, and cost-effectiveness.

Rigid PVC performs well at low (-20°C) and high (135°C) temperatures. It has many industrial applications in the food, building, household appliance and automotive sectors.

Recycled Rigid PVC

For the production of extruded profiles, pipes, gaskets and soft liners, Plasticol also offers customers the 100% recycled rigid PVC option, which retains almost the same characteristics as the base material. The main limits are related to colors and finishing touch.

Polipropilen – PP

Polypropylene (PP) is a thermoplastic raw material that belongs to the Polyolefin family, and it is widely used in several industrial applications and sectors. PP is lighter than PVC and has excellent resistance to chemical agents and high temperatures (120°C). Compared to techno polymers, PP has low flexibility, abrasion and compression performance.

PEHD

High Density Polyethylene is the world’s second most widely used plastic material. The properties that make it so attractive in the industry are its dimensional stability, processability, lightweight, low friction coefficient, waterproofness and excellent resistance to corrosion, abrasion, impact and chemicals. Depending on its molecular weight, polyethylene finds applications in various sectors and is suitable for food contact.

ABS

Acrylonitrile Butadiene Styrene or ABS is a plastic material widely used in industry for its high degree of impact and heat resistance, lightweight and hardness.